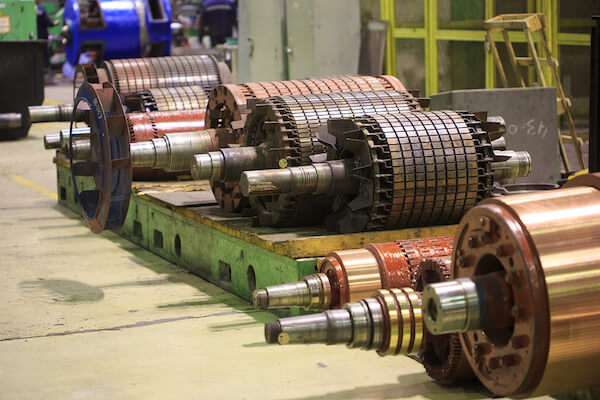

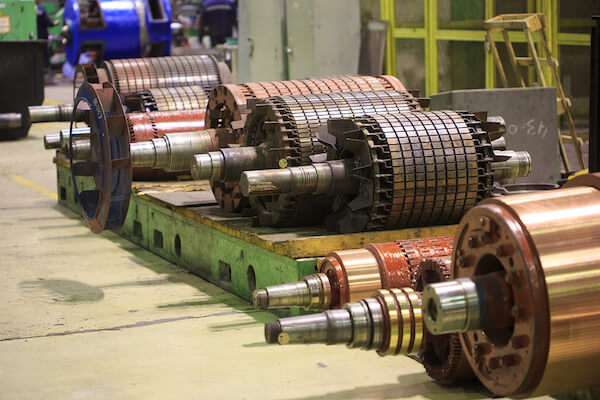

The stator core is made up of thousands tens of thousands or hundreds of thousands of individual steel laminations.

What are stator laminates made of.

Heat often follows eddy current production.

The stator core is made up of a stack of round pre punched laminations pressed into a frame which may be made of aluminium or cast iron.

Thin silicon steel plates are stacked on top of one another around the center preventing eddy current flow.

Cools the stator core.

1 the stator windings and 2 the stator core.

As such there is a need to laminate the stator core and insulate each layer.

1 the stator windings and 2 the stator core.

These laminations can be stacked loose welded or bonded together depending on your application.

The inner surface of the stator is made up of a number of deep slots or grooves around the stator.

Motor output heat rise weight and cost are only a few of the characteristics which are profoundly influenced by the selection of core material.

The laminations are basically round with a round hole inside through which the rotor is positioned.

Stator laminations reduce eddy current by insulating the core.

A turbogenerator stator is comprised of two major components.

Laminations sheets are used instead of a solid pice to reduce eddy current losses.

Modern laminations are comprised of silica steel cold rolled and grain oriented as specific designs might require.

With the eddy current reduced the stator core can maintain constant power keeping your motor running.

In a generator the stator converts the rotating magnetic field to.

In an electric motor the stator provides a rotating magnetic field that drives the rotating armature.

Laminations are the steel portions of the stator and rotor consisting of thin lamination sheets stacked together.

The stator is the stationary part of a rotary system found in electric generators electric motors sirens mud motors or biological rotors energy flows through a stator to or from the rotating component of the system.

Why is the stator core laminated.

The stator core is made up of thousands tens of thousands or hundreds of thousands.