Our epoxy and additives are formulated to provide maximum physical properties and at the same time to be as easy to use as possible.

West systems laminating epoxy.

West system products are now distributed worldwide and sold through full service retailers.

West system epoxy was created by gougeon brothers sailors builders and formulators who know the engineering and the chemistry required for high performance composite structures.

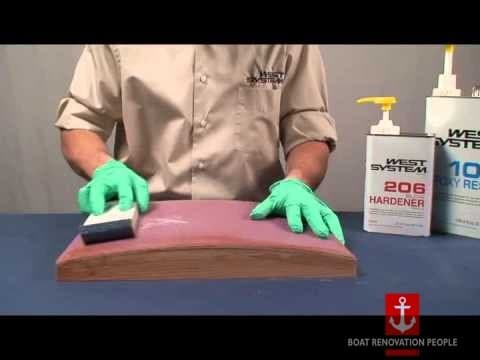

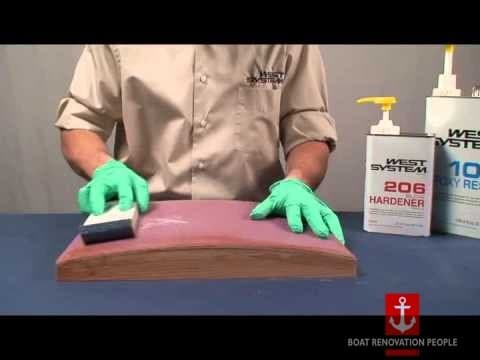

Apply enough epoxy to saturate the fabric and the wood below.

Atl composites has enjoyed steady growth in australia for over 40 years.

Much of our extensive epoxy research and development in the gougeon test lab is driven by the needs of our valuable west system customers.

Don t force the epoxy into the cloth which may trap air in the fabric and show through the clear finish.

However we continue to stay in close contact with our epoxy customers.

If you are considering a boat repair or building project your first decision concerns whether epoxy is the best product for your application or if you should instead consider a polyester or vinylester resin gelcoat repair product or an adhesive.

We are an employee own family run organization that has maintained our performance driven development of marine epoxies since the company was founded in 1969.

Dispose of epoxy resin hardener and empty containers safely.

Today west system epoxy is a marine industry standard used for everything from basic long lasting repairs to the construction of high performance composite structures.

A composite may be any number of layers of the same material or combinations of different materials.

Clean epoxy resin or mixed epoxy residue with lacquer thinner acetone or alcohol.

An extensive distribution dealer network has been established in every state and territory to ensure.

West system epoxy resin and hardeners are the base components of two part marine grade epoxy originally developed specifically for use in boat building.

Clean epoxy hardener residue with warm soapy water.

West system epoxy combined with additives can be used for filling and fairing holes and voids.

Follow all safety warnings on solvent containers.

Adding these filling agents to blended epoxy resin and.

Our full time technical staff fields.

Dip the brush in the epoxy and lay the epoxy on the surface with light even strokes.

Safe disposal of epoxy materials.

Each epoxy filler possesses a unique set of physical characteristics but they can generally be categorized as either adhesive high density for bonding applications or fairing low density for sanding and fairing applications.